By / Norm Grusnick

Insulation is one of the main elements that can help building design engineers create more efficient buildings, meet increasingly stringent energy codes, and find ways to improve sustainable building operations. The trends in building designs are constantly evolving as architects and engineers find new ways to improve building comfort, design, and efficiency.

In looking at future building trends it doesn’t take long to see that energy efficiency is a prime concern today. Requirements are becoming more stringent in today’s green building designs.

Presently, ASHRAE data shows that buildings account for approximately 40 percent of energy consumption. Finding ways to reduce this energy draw is the key to future global sustainability of our building stock.

This is where insulation becomes a key factor that can help building designers create more efficient buildings and meet today’s more stringent codes and energy usage requirements, says insulation manufacturer Johns Manville in an article for SNIPS magazine. The company manufactures Microlite Black PSK, black duct wrap created specifically for aesthetic applications.

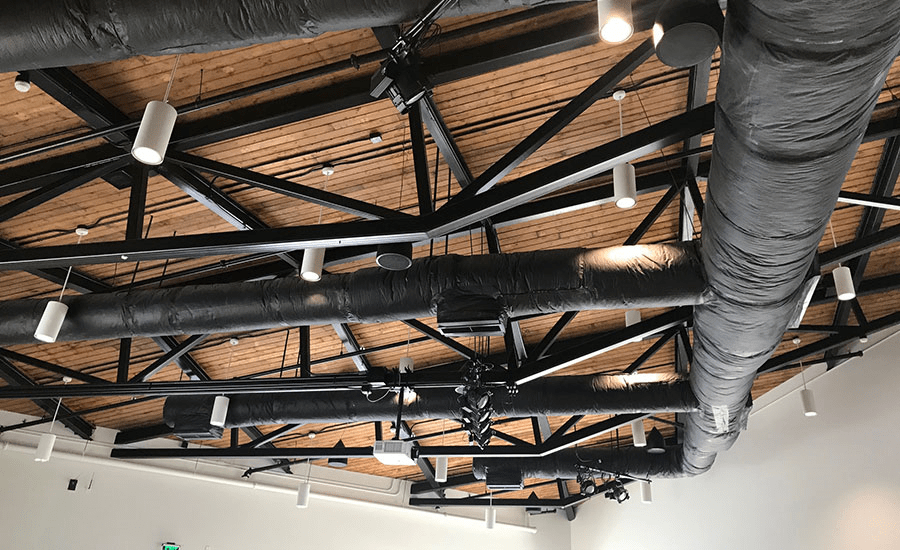

“However, as building design trends evolve and change, we are seeing an increased emphasis on utilizing spaces that have historically been tucked behind façades,” says the article. “Just walk into any restaurant or coffee shop, and look up; you’ll see that designers have left the ceiling exposed, ducts, pipes, and all.”

Exposed ceilings also bring new challenges. Many ducts, warm and cold, may need to be insulated to help achieve the goals of net zero design. “Also, as insulation is not typically designed to be left exposed, designers have had to decide between leaving duct systems uninsulated or choosing an insulation that does not fit into the design concept,” says Johns Manville.

Painting insulation after the fact to match a motif voids the UL 723 rating. Not insulating is not recommended as uninsulated duct runs less efficiently than insulated duct, but it also runs the risk of forming condensation on the duct surfaces. This could lead to mold and mildew growth and other issues.

In addition to providing temperature and condensation control, insulation can also be integral to controlling the acoustics of the space, which is a key component to many of the new building standards like LEED or WELL Building Standard.

“As the need to control thermal and or acoustic properties of exposed duct systems has become more pressing, the insulation industry has responded with materials that are designed with aesthetics in mind,” says Johns Manville. These materials have different outward finishes.

The insulation industry now has matte finish black coated duct wrap with matching tape and white duct wrap with matching tape, manufactured by Johns Manville. This gives designers plausible options to enhance the aesthetics and viability of open exposed ceiling systems.