Milwaukee Tool is Building the Future, One User at at Time

By / Jessica Kirby • Photos courtesy of Partners in Progress

At Milwaukee Tool, product development starts from the end user. The process is focused on user-based design considering the heavy-duty operator from the time they wake to the time they sleep and the effects products have on the body. The results are holistic, encompassing, and embrace the entire human experience—not as the end result, but as the place from which all innovation begins.

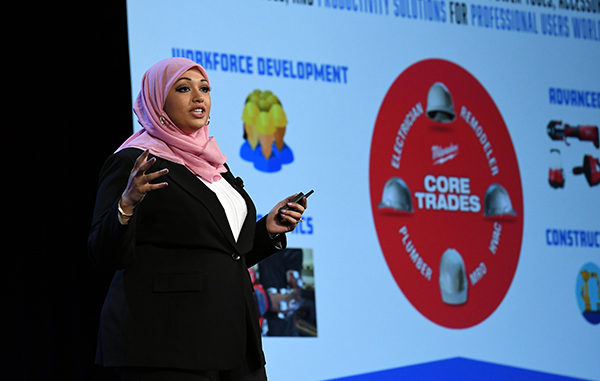

“We aren’t just looking at the user experience on the job site either,” says Tauhira Ali, senior manager of construction technology at Milwaukee Tool. “We have the ability to really focus in on what a tool looks like, how it is used, how it breaks, how to fix it—from cradle to grave, we develop everything from an ethnographic stand point, including physics, technical perspectives, and electronics.”

Ali has worked in the automotive, aerospace, robotics, and manufacturing industries. Before joining the company seven years ago, she had never found a company so people-focused while still having a hand in developing some of the world’s foremost technology. “I came for a tour of Milwaukee Tool, saw how authentic the process is, and never left,” she says.

Safety and ergonomics are the main factors driving product development. “We consider how you hold the tool and the environment you are using it in, and the tools are optimized for exactly the practical application they are intended for,” Ali says. “Everything, whether it is a plunge cutting operation or a table saw, or whether it is weighted or used overhead, it is completely ergonomically constructed.”

Using electromyography, Milwaukee Tool researchers study the body’s reaction to each tool and identify the ways in which each muscle is affected by its use, including how they contract and when, and how the body, in general, is triggered. This allows the team to analyze wear and tear on the body and develop ways to minimize any potential damage.

“We are innovating construction processes, too,” Ali says. “Construction is more than building buildings. It is building the infrastructure of how people live, work, and thrive.

“I was talking with an estimator in Seattle and she had never been to a job site in her life. But, she took me to the window and said, ‘Look, we built this and that’. The fabric of a city is what people build. We help people create a legacy and make their lives better while doing it.”

Milwaukee Tool’s ONE-KEY™ connected platform is a prime example of how the company’s development is improving people’s lives as they work—the cloud-based technology allows users to change the mode, torque, steady-state, and slowdown feed remotely so the tool’s settings are optimized to meet the operator’s exact needs the minute it turns on. It is also used for inventory control and to track usage—ONE-KEY empowers users to record the number of successful crimps in crimpers and schedule lights by using a mobile device.

“I was part of the development of that process and sat with a team of 60-80 people all focused on one platform,” Ali says. “It was so cohesive. We focused on analyzing the workflow. It was never about building a better drill or how to put a hole in something, but about questioning the benefit of making that hole. It is an incredible way to look at things. You may discover that you don’t really need a hole but a different workflow all together.”

Inspiring change, honoring the construction process, and creating a better landscape for the workforce is the foundation of the company’s growth strategy. “We have profound respect for those in trades and everything we do is about respecting what they do.”

Milwaukee Tool’s facilities are in-house, which means an idea can go from vision to 3D printed prototype in 24 hours or less. “This is part of the company’s 100 year legacy,” Ali says. “We move rapidly and have dedicated teams focused on that person at the end of line. We have the best tool makers in the business, and they are willing to push themselves to move quickly and with unrivaled innovation.”

The company’s most recent release, MX Fuel (see page 14) is revolutionizing battery use and power storage, and is just the beginning when it comes to Milwaukee Tool’s future development plans.

“Milwaukee Tool is the kind of company that is launching one product while finalizing the next generation,” Ali says. “There is so much in the pipeline, and each product family has hundreds of components. Whether it’s a charger, a jacket, or a saw, everything in the platform has an ecosystem and platforms that double every couple of years. MX is just the beginning and at the cusp of where the industry will continue to move.

“It is great working with people who are literally working to build the future of America,” Ali says. ▪