VETS Group leverages more than 100 years of proactive, opportunity-seeking expertise to tackle a niche market and foster a family of excellence.

By / Jessica Kirby | Photos / VETS Group

In 1921, Fanny Rayner was eavesdropping on a party line. She overheard her husband Fred’s employers talking about laying him off, and she jumped right in. “Don’t worry about it,” she interrupted. “Send him home and tell him he quits!”

This was the beginning of VETS Sheet Metal, a 102-year-old, family-run company of risk-takers, go-getters, and challenge-seekers that has evolved with every decade and continues to break new ground with each generation.

Fred and Fanny met during WWI. Fred was injured while serving and Fanny was his nurse. They returned to Edmonton after The War, and after Fanny relieved Fred from his going-nowhere job, he founded VETS Sheet Metal, named to honour the war veterans he fought with and later employed.

Fred made his way to work by bike or streetcar each morning with a roll of galvanized sheet metal tucked under his arm. He eventually invented the VETS Sheet Metal Supreme gas furnace, a twist on a simple gravity furnace that achieved better efficiency. It became a common fixture in post-War Edmonton homes and partially defined Fred’s mark on the company’s history.

In 1944, Fred’s son Al took over the company and forged new paths into the city’s commercial and institutional construction markets. He grew the company to employ more than 100 people, and it became the first Lennox dealer in Alberta. He employed his son David, who eventually took the reins in 1974 and spent three decades improving efficiency and productivity with technology upgrades, a strong safety culture, and a family of long-term employees.

Today, Sean Rayner leads the innovative, energetic company that stays connected to its roots but keeps a brave eye on the future. The company was rebranded VETS Group under Sean’s tenure and is nimble and responsive, fuelled by a dedicated team and zero desire to sit around waiting for the future to happen.

“Every one of the generations had its own mark and stamp on the business that shaped how it has evolved,” Rayner says. “When I took over in 2005, we were a small job shop fabrication company also doing small industrial HVAC projects. We refocused on construction and industrial construction needs, particularly in the then-growing oil and gas industry.”

Business grew rapidly through the boom, and so did VETS Group. “Knowing there is a cycle in the oil and gas business, we knew it wouldn’t last forever,” Rayner says. “Before we had to, we started specifically working on our building expertise and developed contacts in the wood business, focusing on dust collection, which is a specialized niche in the sheet metal business.”

In 2016, the VETS Group acquired AirTek Pneumatics with locations in Kelowna and Surrey, British Columbia. Through that acquisition and building its expertise in that market, VETS Group managed to shift the business from 85% industrial oil and gas and 10-15% other work to the opposite when oil and gas declined in 2016. “We shifted to 85-90% dust collection and 10-15% other things,” Rayner says. “So, the intentional pivot paid off.”

Delving into the niche market introduced some challenging but deeply rewarding projects. A specialized press exhaust system for an OSB plant, for example, hit a roadblock when the price and availability of materials changed abruptly from the year in which the project budget was created.

The plans originally called for a free-standing stack in ¾ inch to ¼ inch stainless fed by stainless piping. But when Russia invaded Ukraine, the price of stainless spiked from $2/pound to $11/pound.

“We couldn’t deliver on our price guarantee, so we reengineered the stack,” Rayner says. “From the original self-supporting stainless stack concept, we built a structural steel supported stack using lighter steel, which we could still get. With creativity and engineering, we were able to save the customer time and fit the project into the original budget.”

In Terrace, BC, VETS Group completed a dust collection system for Skeena Bioenergy, a pellet plant. VETS worked with the plant and equipment manufacturer and supplied a cyclofilter—a unique combination of a cyclone and baghouse. “It was a show piece because the pellet mill is right downtown and emissions control is critical to keeping the neighbours happy,” Rayner says. “We were able to do that.

“People shy away from baghouses because of the maintenance required, but this mill hasn’t changed the bags in over three years. The efficiency of our design was off the charts.”

Today, VETS Group designs, engineers, manufactures, and installs complete dust collection systems.

“I think what we are doing to create our success going forward is owning the expertise and the design of the specialization that made us successful,” Rayner says. “We are not waiting for someone else to design the project. We are the direct link to the customer. That is what sets us apart in our market.”

Of course, labour shortages, delayed materials, and inflationary cost increases are as haunting in BC and Alberta as anywhere else.

The BC labour market is challenging enough—finding people with an extremely narrow field of experience is an added conundrum. “We take pride in low labour turnover, so when we get people, they are the right people,” says David Brown, Branch Operations Manager at the VETS Group location in BC.

“I would prefer to work short staffed with the right group than be top heavy with people who don’t quite have the skill set or team buy-in.”

For that level of experience and mentality, the workforce earns premium wages and the challenge of interesting work that is never the same two days in a row.

“That is what excites the people working in the shop,” Brown says. “It is always something they have never built before.”

But that’s not even the best part. Brown says one of the company’s most important accomplishments has been discovering its core values.

“Core values are discovered, not created,” he says. “We’ve had the good fortune of finding ours with people who have been working with us for decades.”

VETS Group core values are a throwback to their military history. They spell the word honour:

Human leadership

Ownership mentality

Nurturing environment

Open communication

United team

Renowned craftsmanship

“I can tell you, it’s what attracted me to the company,” Brown says. “I’ve been in the industry 30 plus years, and one thing missing from my previous work was passion in the trade and feeling like you are part of something. When I was recruited by VETS and sat down with Sean, Leo, and Bill, it was an instant connection, and I had immediate buy-in. We were speaking the same language.”

If only it were that simple every time. For employees who didn’t necessarily share the mindset, getting buy-in to the company values was a little bit more challenging. Brown came on during the integration of the acquisition in 2016, so he had the benefit of a clean slate and gave the crew the same opportunity to buy in and see what advantages that might bring to their daily work lives.

“We knew once we got the ball rolling, it wouldn’t be as challenging,” he says. “That really solidified when we switched locations from Surrey to our new office in Burnaby.”

When the opportunity arose to move the BC location, it also brought the chance to start fresh. The management team worked hard to shed the previous vibe and brought the workforce around to the new space, so they felt included in the process.

“The whole team really got involved with the move and making it a new home,” Brown says. “The buy-in was incredible. They wanted to be part of the demo work and of the whole process. It was huge.”

The future manifested from there. In the new building, everyone from first-year apprentices to long-time members of the team felt at home. One said he wished he could have been in the building 20 years ago.

“The values show in how the team presents themselves,” Brown says. “If you want to be a pro, you must act like a pro.”

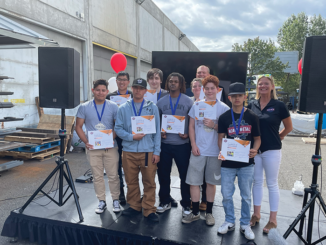

Rayner says the ownership mentality is crucial to the company’s success. In fact, he leveraged the employees’ passion and launched an employee shareholder structure in celebration of the company’s 100th year in business. At the time of writing, VETS Group had 27 employee shareholders.

“There were a lot of people working in the business who treated it like it was their own,” he says. “We have been an organization of four generations of family ownership with a single successor and shareholder per generation. But the core values and the company’s success are not only the Rayners’ legacy.”

Moving forward, VETS Group will capitalize on renewed activity in the mining industry and new or renewed service and optimization across sectors.

The niche work also spreads across other industries, including agriculture, biomass, forestry, mining, food manufacturing, and import/export terminals.

“We are continuing to develop the market in the dust industry, including meeting demand for assessment and consulting work in various industries,” Rayner says. “We are working on addressing those needs across the country, and we have customers who want to know if we can meet their needs in the United States and other Canadian locations.”

“Our focus also continues to be workforce training and development to meet expectations for growth,” Brown adds.

“We are hearing about fears of slow down and recession, but we are so specific in specialization that we are hoping to see one of our best years ever,” Rayner says.

Learn more at | vetsgroup.com ■