Turning vanes in HVAC ductwork are perhaps one of the greatest sources of conflict between sheet metal contractors and HVAC engineers. Why? Because many mechanical/sheet metal contractors believe turning vanes can cause the ductwork to become less efficient by increasing the pressure drop in the system and by adding expense and time to the installation. This belief seems to be based on simple logic: when there is more surface area exposed to the airflow, the amount of friction will be increased, and the harder the fan must work to achieve the required airflow.

Turning vanes in HVAC ductwork are perhaps one of the greatest sources of conflict between sheet metal contractors and HVAC engineers. Why? Because many mechanical/sheet metal contractors believe turning vanes can cause the ductwork to become less efficient by increasing the pressure drop in the system and by adding expense and time to the installation. This belief seems to be based on simple logic: when there is more surface area exposed to the airflow, the amount of friction will be increased, and the harder the fan must work to achieve the required airflow.

In some cases where the HVAC system is having difficulty supplying the required volume to all zones, contractors want to recommend the removal of every second turning vane to reduce the friction in the duct. This practice is in violation of SMACNA turning vane spacing requirements, because it decreases the uniformity of the airflow and increases system pressure drop. The real question is, does reality match up with popular beliefs?

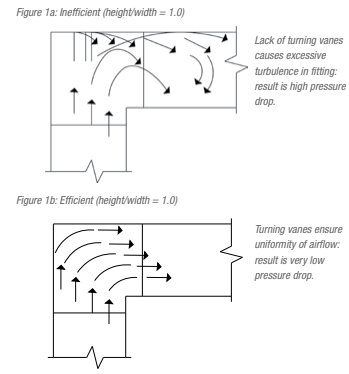

When there is a change in direction in a duct that has no turning vanes, the duct walls must absorb the sudden impact of the air in order to re-direct the airflow to the desired direction. Turning vanes assist the airflow in making a smoother and more gradual change in direction, thus transferring less impact and less force to the duct walls. While the turning vane surfaces do add a small amount of friction, the amount of energy lost to friction from the vanes is very little compared to the energy lost in the impact resulting from the airflow taking an abrupt change in direction. Figures 1(a) and 1(b) show the airflow resistance that occurs in a 90 degree elbow with and without turning vanes.

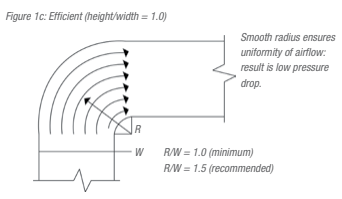

From these figures it can be seen that the elbow with turning vanes is much more effective than the same elbow without the vanes. If the client desires a less expensive installation, the design engineer may specify a radius elbow without turning vanes. A radius elbow is still highly effective but with a recommended 1.5 center line radius it occupies a lot more space. Figure 1(c) shows a radius elbow.

In all cases above it can be seen that as the airflow changes direction more gradually, the fitting pressure drop decreases and with it the energy required by the system fan to supply the desired airflow volume.

Turning vanes are proven very valuable for reducing pressure losses and increasing system efficiencies. Designers should always specify fittings with the highest possible efficiency to increase system efficiency at every available opportunity. Contractors should never take it upon themselves to add or remove turning vanes from the engineer’s design.

References

American Society of Heating, Refrigeration, and Air-Conditioning Engineers Inc. (ASHRAE) 2017 ASHRAE Handbook-Fundamentals

Sheet Metal and Air Conditioning Contractors National Association Inc. (SMACNA) HVAC Duct Construction Standard-Metal and Flexible Third Edition 2005.