By / Shephane McShane

This article was republished with permission from its original source: Partners in Progress magazine, volume 12 issue 2 May 2018. Read more at www.pinp.org.

The construction market seems to be evolving at a speed unmatched in previous history. The demands for collaboration, problem solving, and rock solid planning processes are driving changes in current communication means. It is critical that the cultural and operational hurdles created by ineffective communication and conflict resolution skills that can hinder the forward progress of your organization be addressed.

Today’s construction industry and the clearly defined path forward include pull planning, multi trade design and fabrication, modularization, and increasingly accelerated schedules. All of these items have one core value in common: Collaboration. The industry is demanding that the trades work together to solve problems more rapidly in order to accelerate the schedule. The era of the dictatorship model where the general contractor openly orchestrates every move are coming to an end in favor of the lean, team-engaged environment. This model thrives where input and active participation are held as paramount. That said, it begs a question. How can we deliver a fully collaborative product to our external clients (those outside of our walls) if we don’t have that same level of collaboration occurring with our internal clients (those inside our walls)?

In the world of construction, the lack of clear communication between positions in management, staff, and field is still very often seen. The reason for its continuance cannot be that, “It’s been that way for years.” As quickly as we are seeing the delivery methods, design strategies, and operational plans evolve, so does the need to become very agile internally and leverage the strengths of many parties in order to meet the common goal of timeliness, safety, and profitability.

So what causes a serious breakdown in communication and, ultimately, productivity and profitability? It could boil down to three very important factors: Lack of defined roles and responsibilities, inconsistency in business practices, and poor culture.

Defined Roles and Responsibilities

Highly successful and progressive contractors understand the need for defined roles. In order to create a scalable, replicable model, each person in the organization must understand what their role is in order to generate a predetermined deliverable. For example, if you took a hard look at your process that ends in a prefabricated assembly, skid, or product, how many people in your organization would be involved in the success or failure of that product being done correctly, per design, on time, and on budget? In order to have any sort of predictability of cost and timeline, it becomes necessary for each person in this chain of events to understand what information or product they receive, what they do with it, and what the expected outcome from them would be. If we have variances in the roles of those handling the submittal, purchasing, design, fabrication, logistics, or installation processes, neither the cost, the quality, nor the timelines of the product would be predictable. In this particular instance, the use of value stream mapping involving those parties who create or use the product (management and labor) would be recommended in order to define the process, including the end result of documentation of each role and deliverable needed by each position identified in the workflow, to create the standardization, clarity, and lean transformation that most organizations seek.

Consistency and Discipline

Consistency in business practices has everything to do with standards. Standards range from the soft skills such as how we do business, how we treat our clients (both internal and external), and what we stand for in the industry, to the hard skills of having defined systems and processes that set the stage for consistency and productivity. An example of a lack of standards and consistency came from a consulting client that was creating installation drawings utilizing the skill set of the foreman running the job as the barometer to dictate how much detail to place on those drawings. So, literally, each job was designed to a completely different standard. This is in stark contrast to those firms who have design levels standardized with specific detail as to what is contained on the backgrounds, what extraneous information is removed, what level of information is created for field use in installing, and how this information flows through to fabrication. In order to determine what thisprocess should look like, those involved in creating and utilizing the information, both staff and labor, should be teaming up to define best practice. Only with consistency in standards, and the discipline to ensure standards are followed, can we reduce the friction and delays that come from the inconsistencies that exist in the organization.

Positive Culture

Culture plays a key role in the success of communication within a firm. The common pitfalls to culture are lack of structure, micromanagement, poor leadership, and lack of discipline. For example, working on improvement initiatives with a company with positive, energetic, supportive culture allows those changes to become adopted and accepted at a significantly higher rate than those firms with a negative or distrustful environment. Trust is the cornerstone of culture and it must be seen at every level in the organization and exist between work groups. A simple way to explore the overall culture of an organization is to test the relationship and trust that exists between project management, superintendents, and field foremen. If that relationship displays trust, aligned vision, shared ambition, and a team spirit, then it is likely the culture of the firm is well intact.

Culture plays a key role in the success of communication within a firm. The common pitfalls to culture are lack of structure, micromanagement, poor leadership, and lack of discipline. For example, working on improvement initiatives with a company with positive, energetic, supportive culture allows those changes to become adopted and accepted at a significantly higher rate than those firms with a negative or distrustful environment. Trust is the cornerstone of culture and it must be seen at every level in the organization and exist between work groups. A simple way to explore the overall culture of an organization is to test the relationship and trust that exists between project management, superintendents, and field foremen. If that relationship displays trust, aligned vision, shared ambition, and a team spirit, then it is likely the culture of the firm is well intact.

It might be said that this level of utopia does not exist in our industry. Perhaps perfection isn’t the goal. The target moves daily, and organizations must be agile enough to respond. The goal of any organization should be to ensure that its members are engaged, aligned in the vision of success for the company, and productive in working together to solve the many challenges ahead. The battle lines in the sand between departments, or “silos” within the organization should not exist. Management, labor, and staff should be focused in their efforts to attain common goals that support all parties. As an industry, we face ongoing pressures regarding schedule, quality, and cost. The solution lies in a coordinated effort of defining roles, creating consistent deployment of business practices, and a positive, supportive culture to ensure success for all. You cannot change an organization. You CAN positively change the culture and processes to benefit the people within the organization to gain the results desired.

–

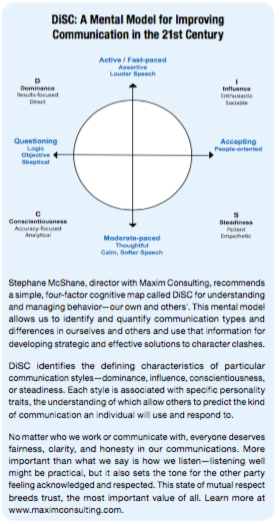

Stephane McShane is a director at Maxim Consulting Group in Denver, CO, where she is responsible for the evaluation and implementation processes with the company’s clients. Stephane works with construction related firms of all sizes to evaluate business practices and assist with management challenges. Visit www.maximconsulting.com for more information.